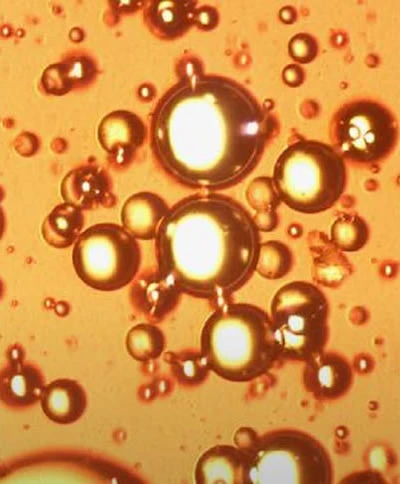

The oil extracted from the subterranean oil layer is accompanied by water and sediment, and inorganic salts such as NaCl, MgCl2, CaCl2, etc. are dissolved in the water. The existence of these substances is very harmful to the processing process, so they must be removed by electric desalination. Since most of the inorganic salts are soluble in water, desalting and dehydration are carried out simultaneously. In order to remove the salt particles suspended in the crude oil, a certain amount of fresh water is injected into the crude oil (the injection amount is generally 5%), and a demulsifier is added at the same time, which is helpful for the breaking of the emulsified film in the emulsifier and the removal of inorganic salts. Removal: After fully mixing, under the action of the electric field, the tiny water droplets are coalesced into large water droplets, and the process of separating oil and water under the action of gravity is called electric dehydration/desalting.

The first generation of electric dehydration/salt technology

Alternating current dehydration/salt technology.

The second generation of electric dehydration/salt technology

Squirrel cage electric dehydration/salt technology.

The third generation electricity dehydration/salt technology

Intelligent pulse AC-DC electricity dehydration/salt technology.

The fourth generation electric dehydration/salt technology

High-speed electric dehydration/salt technology.

The fifth generation of electric dehydration/salt technology

Electrostatic coalescence dehydration/salt technology.

The sixth generation of electric dehydration/salt technology

Pulse composite electric field electric dehydration/salt technology.

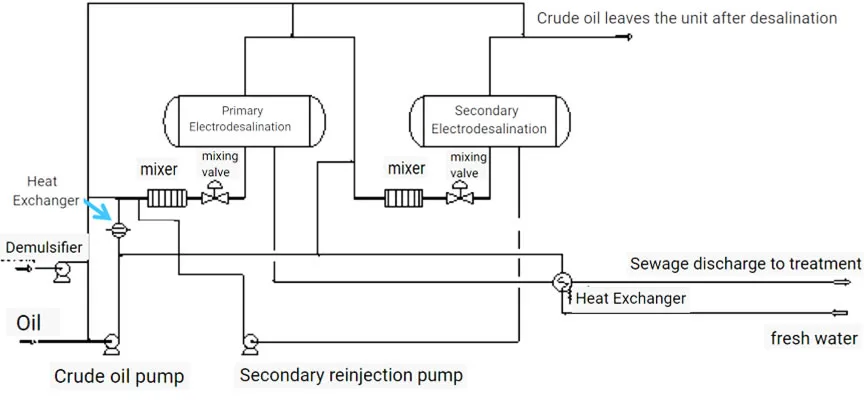

The fresh water must be exchanged with the electric desalination drainage to 80-90 ℃ and then used as the electric desalination water injection.

The injection points of water injection for electric desalination are set to 3, one injection point in front of the primary and secondary mixing systems, and a new injection point in front of the heat exchanger. The water injection volume is about 1% (if necessary). The mixed effect of the pipeline, so that the salt in the crude oil is dissolved in the water, and it acts together with the demulsifier, which is beneficial to the desalination of the crude oil.

The secondary electric desalination tank is injected with fresh water, and the secondary electric desalination drainage is used as the primary electric desalination water injection. Considering the actual operation situation, both primary and secondary lines need to have double lines that can be injected with fresh water, and secondary drainage also needs to have double lines to drain directly to the sewage pipeline outside the tank.

The two-stage electric desalination process is adopted, one tank is one stage, and the desalination process flow is shown in the following figure:

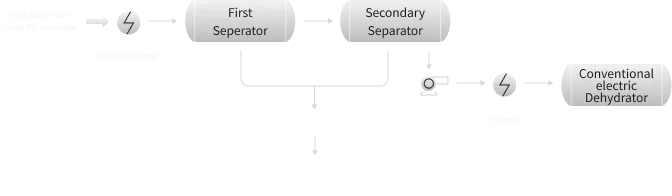

Electrostatics Ccoalescence Technology

Most advancedtechnology in the world, which belongs only to us except that Norseland has the similar technology.We work with China's top petrochemical research institute, it has spent us more than 10years for research and practical application.Norseland used this technology in 10 places in the world, we used 4places about.Appropriate working condition:high water content of crude oil with high denseness.Working effect: High efficiency dehydration.

Cnooc Bozhong 34-2 Offshore Platform Electric Dehydration/Desalting Skid Installation

Cnooc 25-2 Platform Electric Dehydrating/Desalting Skid

CNOOC 36-1CEPK Offshore Platform Electric Dehydration/Desalting Skid Installation

Cnooc PY 4-2 Offshore Platform Electric Dehydration/Desalting Skid

CNOOC Jinzhou 20-2 Offshore Platform Electric Dehydration/Desalting Skid

Lufeng 12-3 Electric Dehydration/Desalting Sled, A Joint Venture Between South Korea's SK Corporation and CNOOC

Complete Set of Electrical Dehydration/Desalting Equipment in Kingfisher Oilfield, Uganda

Packging Photos of Complete Set of Electrical Dehydration/Desalting Equipment in Kingfisher Oilfield, Uganda

Cnooc Liuhua 11- 1FPSO Phase I&II Electric Dehydration/Desalting Skid Installation Transformation

LF7-2 Electric Dehydration/Desalting Project of New Field Oil Company and CNOOC Contract

PY4-2/5- 1 Electric Dehydration/Desalting Equipment of Conocophillips and CNOOC Joint Venture

Tahe crude oil

before desalination

Tahe crude oil

after water injection and mixing

Tahe crude oil

after desalination

Luoyang Zhengyuan Petrochemical Co., Ltd. is the first-level supplier of China National Offshore Oil Corporation and the supplier of Sinopec materials and equipment.

The company’s technology center is equipped with multiple (sets) simulation test devices such as electric desalting/dehydration simulation test platform, electrostatic coalescence electric dehydration test device, and sewage treatment experimental device, as well as complete inspection and testing instruments.

With AC and DC and pulse dual technology

Remarkable effect of energy saving and consumption reduction

Strong desalination ability, fast oil-water separation, and less amount of demulsifier

The operation fluctuation of the device is small and the stability is strong

Long lasting

Zhengyuan Petrochemical

Create the greatest value for customers

Provide the best quality products and services

+861589659239

zypetrochem@gmail.com

No. 8, Xinxin Road, Luoxin Industrial Park, Xin'an County, Luoyang, China

WhatsApp

WhatsApp