Copper-nickel alloys, often referred to as CuNi or cupronickel, are a class of metallic materials primarily composed of copper and nickel, with small additions of other elements like iron and manganese.

These alloys are highly valued in the marine industry for their exceptional properties, making them ideal for a wide range of ship accessories and components.The main engineering grades of copper-nickel alloys were developed for naval condenser and seawater pipework applications.

Outstanding

Performance

Widely

Applicable

| ASTM | Name | Cu | Ni | Fe | Pb |

| C70600 | 90-10 copper nickel | ~89 | 9.0-11.0 | 1.0-1.8 | <0.05 |

| C71500 | 70-30 copper nickel | ~69 | 29.0-33.0 | 0.4-1.0 | <0.05 |

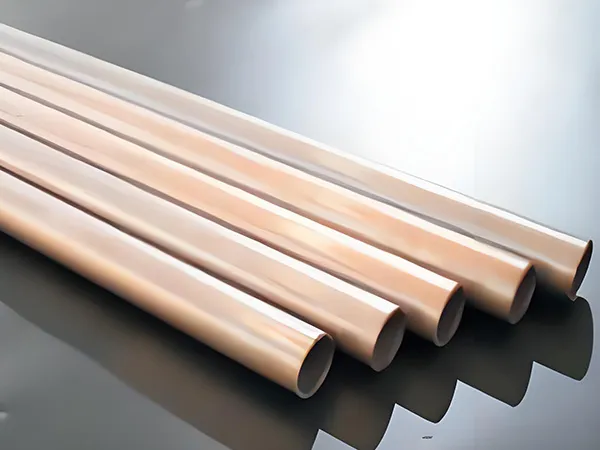

Pipes

This alloy typically contains 90% copper and 10% nickel, along with small additions of iron and manganese. It is the most commonly used wrought copper alloy for marine engineering due to its excellent balance of corrosion resistance, biofouling resistance, and cost-effectiveness.

Comprising 70% copper and 30% nickel, with similar beneficial additions of iron and manganese, this alloy offers higher strength and can withstand more aggressive seawater velocities and higher temperatures compared to the 90/10 alloy. It is often preferred for more demanding applications.

Cnooc Huizhou 25-31 Offshore Platform Electric Dehydration/Desalting Skid Installation

Electrostatic Coalescence Technology of CNOOC 13-1 Offshore Platform

CNOOC CEPK Offshore Platform in Suizhong 36- 1 Oilfield- Electric Dehydrator Skid

CEPA Offshore Platform for Caofeidian 6-4 Oil Field Development CNOOC Project

Custom Copper-Nickel Ship Pipe Fittings: Reliable Solutions for Modern Marine Engineering

In today’s shipbuilding and marine engineering industry, the smallest components can have the biggest impact. Among ...

Why Copper Nickel is the Ideal Choice for Ship Condenser Tubes

In modern shipbuilding and marine engineering, the material selection for condenser tubes is a critical decision that ...

How to Maintain Copper-Nickel Alloy Ship Fittings: A Comprehensive Guide for Long-Term Marine Performance

Copper-nickel alloys have earned a solid reputation in the shipbuilding and marine engineering sectors. These materials ...

Zhengyuan Petrochemical

Create the greatest value for customers

Provide the best quality products and services

+861589659239

zypetrochem@gmail.com

No. 8, Xinxin Road, Luoxin Industrial Park, Xin'an County, Luoyang, China

WhatsApp

WhatsApp