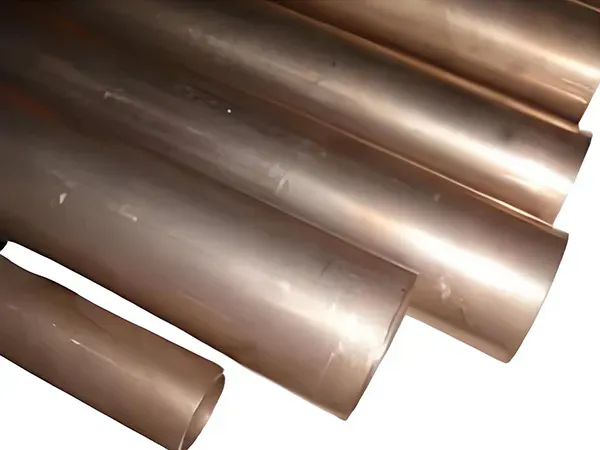

In modern shipbuilding and marine engineering, the material selection for condenser tubes is a critical decision that directly affects engine performance, maintenance schedules, and overall vessel efficiency. Condenser tubes form the backbone of a ship’s cooling system, transferring heat from engines to seawater. Among available options, copper nickel (Cu-Ni) alloys have become the preferred choice for shipbuilders worldwide. But what makes copper nickel the go-to material in marine environments?

Advantages of Copper-Nickel Alloy Marine Condenser Tubes

Exceptional Corrosion Resistance in Seawater

Marine conditions are harsh. Constant exposure to saltwater, combined with oxygen and varying temperatures, accelerates corrosion in many metals. Copper nickel alloys, typically in 70/30 or 90/10 copper-to-nickel ratios, offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking, ensuring condenser tubes remain intact and reliable even after years of continuous use.

Pro Tip: For ships operating in high-salinity regions, selecting 90/10 Cu-Ni can further extend tube lifespan and reduce maintenance frequency.

Natural Resistance to Biofouling

Marine growth—such as algae, barnacles, and microorganisms—can cling to metal surfaces, reducing heat exchange efficiency. Copper nickel alloys naturally resist biofouling, significantly lowering maintenance needs and cleaning downtime. This advantage is especially critical for commercial vessels and naval fleets that require uninterrupted operation.

Superior Thermal Conductivity

Efficient heat transfer is the primary function of condenser tubes. Copper nickel alloys combine good thermal conductivity with exceptional corrosion resistance, ensuring engines maintain optimal operating temperatures. This improves fuel efficiency, reduces wear on mechanical components, and prolongs engine life.

High Strength and Durability

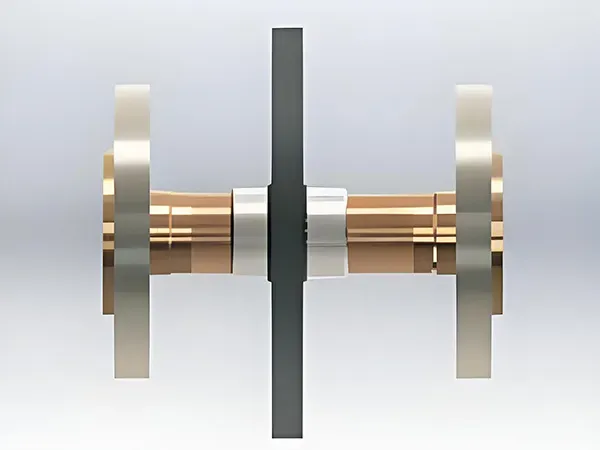

Copper nickel alloys also boast impressive mechanical strength and toughness, resisting erosion from high-speed seawater flow and maintaining integrity under high-pressure conditions. This makes them ideal not only for condenser tubes but also for other key marine components like piping systems, heat exchangers, and evaporators.

Easy Fabrication and Installation

Shipyards benefit from copper nickel’s flexibility and ease of fabrication. Tubes can be bent, welded, and installed with precision, reducing production time and cost while maintaining high reliability in demanding marine environments.

Long-Term Cost Efficiency

Although Cu-Ni tubes may have a higher upfront cost compared to alternatives like stainless steel or titanium, their long service life, reduced maintenance, and reliable performance make them a cost-effective choice over time. Ships equipped with Cu-Ni condenser tubes experience fewer failures, longer intervals between replacements, and lower overall operational costs.

Choosing the right material for condenser tubes is more than a technical decision—it impacts vessel performance, maintenance frequency, and operating costs. Copper nickel stands out for its corrosion resistance, antifouling properties, thermal efficiency, strength, and durability. It is the benchmark material for reliable, long-lasting condenser systems.

Investing in high-quality copper nickel tubes today ensures safer, more efficient, and cost-effective marine operations tomorrow. Don’t let corrosion or biofouling compromise your ship’s performance.

Request a quote for premium Cu-Ni condenser tubes.

Contact our marine engineering experts for a consultation tailored to your vessel.

Ships equipped with copper nickel tubes operate longer, cleaner, and more efficiently—secure your vessel’s performance now.

Custom Copper-Nickel Ship Pipe Fittings: Reliable Solutions for Modern Marine Engineering

2026-01-28 03:40Why Copper Nickel is the Ideal Choice for Ship Condenser Tubes

2026-01-23 03:39How to Maintain Copper-Nickel Alloy Ship Fittings: A Comprehensive Guide for Long-Term Marine Performance

2026-01-15 01:25Why Copper Nickel Alloys Excel in Marine Environments: Key Advantages and Real-World Applications

2026-01-09 00:39Address: No. 8, Xinxin Road, Luoxin Industrial Park, Xin'an County, Luoyang, China

E-mail: zypetrochem@gmail.com

Phone: +861589659239

Zhengyuan Petrochemical

Create the greatest value for customers

Provide the best quality products and services

+861589659239

zypetrochem@gmail.com

No. 8, Xinxin Road, Luoxin Industrial Park, Xin'an County, Luoyang, China

WhatsApp

WhatsApp