Has electrode salt/water explosion-proof transformer certificate, special equipment production license, ISO9001 quality system certification, etc. China Classification Society CCS certification, BV, DNV and other international certifications are CNOOC, CNPC, Sinopec first-class material and equipment suppliers.

Contact Us

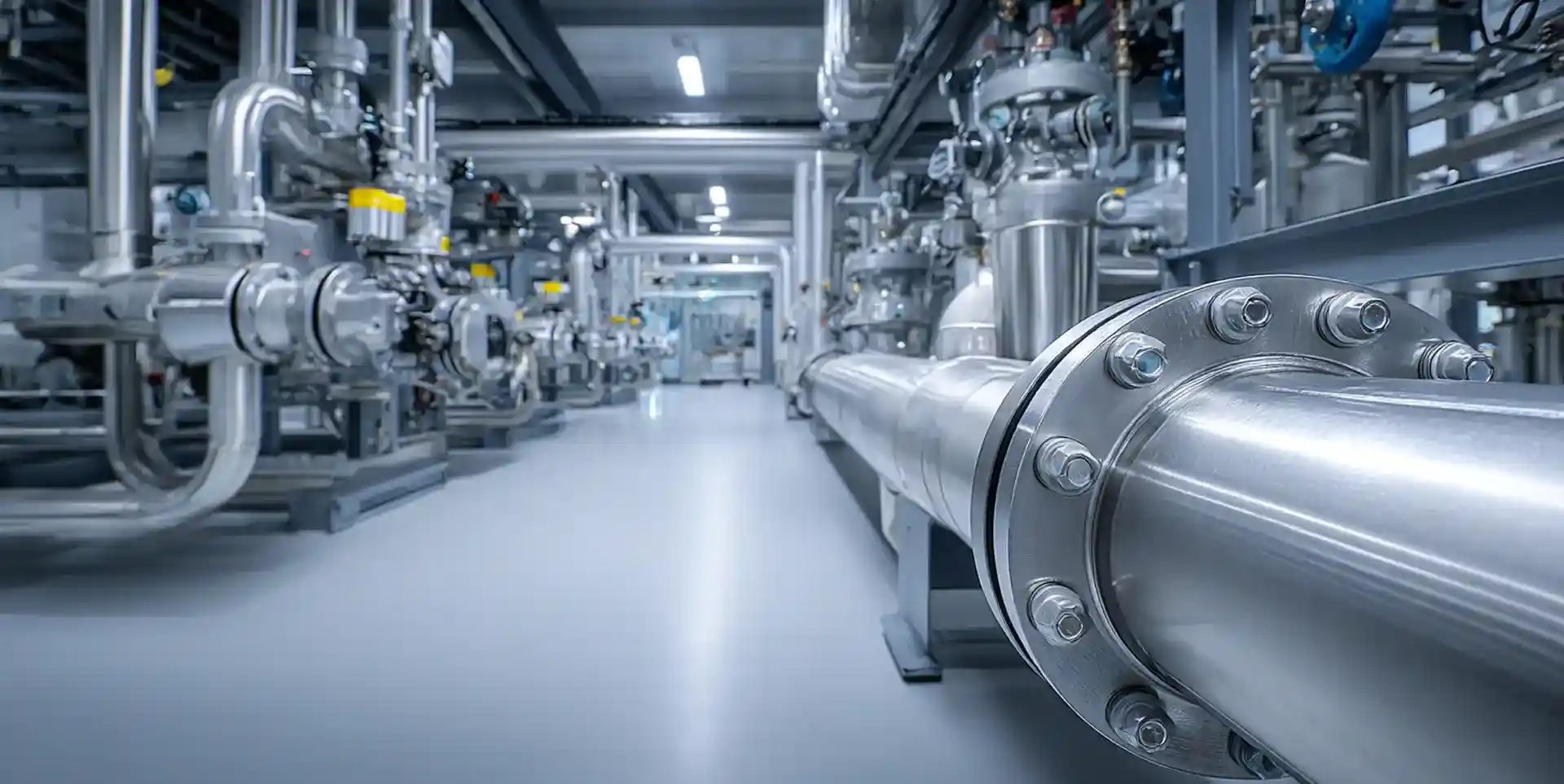

Oil water separators (OWS) are critical pieces of equipment on ships and offshore platforms, playing a vital role in preventing marine pollution. These systems are designed to separate oil from various wastewater streams generated during operations, ensuring that discharged water meets strict environmental regulations.

Ships and offshore platforms generate oily wastewater from several sources, including:

Bilge water: A mixture of seawater, oily residues (fuel oil, lubricating oil, hydraulic oil), grease, detergents, solvents, and other contaminants that collect in the lowest part of a ship's hull.

Machinery leaks and spills: Accidental releases of oils and fuels from equipment.

Cleaning operations: Water used for cleaning tanks, decks, and machinery that may become contaminated with oil.

Produced water (offshore platforms): Water that naturally comes to the surface along with oil and gas from a reservoir, often containing dissolved and dispersed oil.

Discharging this untreated oily water directly into the marine environment can have devastating effects on marine life and ecosystems. To mitigate this, international regulations, primarily driven by the International Maritime Organization (IMO) through the MARPOL 73/78 convention, mandate the use of OWS to treat these waste streams before discharge. The most common standard requires the oil content in discharged water to be no more than 15 parts per million (ppm).

The fundamental principle behind OWS operation is the difference in density between oil and water. Oil is generally less dense than water, causing it to float on the surface when given time to separate. OWS systems leverage this principle through various mechanisms, often in multiple stages:

Inlet and Pre-Treatment: Oily water enters the OWS, where a strainer or coarse filter may remove larger debris.

Primary Separation: This stage aims to remove the majority of the free oil. Common methods include:

Gravity Separation: The most basic method, where the oily water mixture is held in a tank or chamber, allowing the less dense oil to naturally rise to the surface and form a layer that can be skimmed off. Internal baffles or catch plates can enhance this process by providing surfaces for oil droplets to coalesce (combine into larger droplets).

Centrifugal Separation: This method uses centrifugal force to accelerate the separation. The mixed fluid is spun at high speeds, causing denser water particles to move outwards and lighter oil particles to remain closer to the center, where they are collected. This method is often more efficient and compact.

Coalescence and Filtration: After primary separation, smaller oil droplets may still be dispersed in the water, forming emulsions.

Coalescers: These are specialized filters or media designed to encourage tiny oil droplets to collide and merge into larger ones. This makes them easier to separate by gravity. Coalescing plates are a common example, where oil droplets stick to the oleophilic (oil-attracting) surfaces and coalesce.

Filters: Further filtration stages remove any remaining solid impurities or fine oil droplets.

Oil Removal and Discharge: Once separated, the accumulated oil is typically removed by an oil skimmer or a dedicated pump and transferred to a waste oil tank for proper disposal ashore or incineration onboard. The "cleaned" water, now with a significantly reduced oil content, is then discharged overboard, provided it meets the regulatory limits, which are continuously monitored by an Oil Content Monitor (OCM). If the oil content exceeds the limit (e.g., 15 ppm), the discharge is automatically recirculated for further treatment.

While the general principles remain, OWS systems can vary in their specific design and technology:

Gravity-based Separators: Rely on the natural density difference, often incorporating coalescing plates. These are common, especially in older installations or for less complex applications.

Centrifugal Separators: Utilize centrifugal force for more efficient and faster separation, capable of handling finer oil dispersions.

Membrane Filtration: Employ semi-permeable membranes to physically separate oil from water, offering high purity levels.

Absorption/Adsorption: Use specialized media like organoclay or activated carbon to absorb or adsorb oil from the water.

Electrochemical and Bioremediation: Emerging technologies that use electrical fields to break emulsions or microorganisms to consume oil, respectively.

The operation of OWS on ships and offshore platforms is strictly regulated by international conventions like MARPOL Annex I, and enforced by flag states and port state control. Key aspects of these regulations include:

15 ppm Standard: The most widely adopted standard for oil content in discharged water from machinery space bilges.

Oil Content Monitor (OCM): All OWS systems must be fitted with an OCM to continuously monitor the oil content of the discharge and trigger an alarm or automatic recirculation if the limit is exceeded.

Type Approval: OWS equipment must be type-approved by relevant authorities (e.g., US Coast Guard, IMO) after rigorous testing.

Record Keeping: Ships are required to maintain an Oil Record Book, detailing all operations related to oily water discharge.

In conclusion, oil water separators are indispensable environmental protection devices on ships and offshore platforms. Their effective operation is crucial for safeguarding marine ecosystems by ensuring that oily wastewater is treated to stringent international standards before being discharged into the sea.

Zhengyuan Petrochemical

Create the greatest value for customers

Provide the best quality products and services

+861589659239

zypetrochem@gmail.com

No. 8, Xinxin Road, Luoxin Industrial Park, Xin'an County, Luoyang, China

WhatsApp

WhatsApp